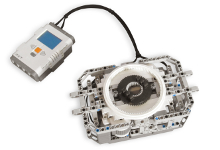

(left) Velodyne interface box.

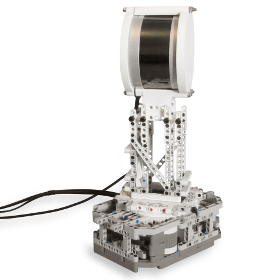

(right) Lego NXT Brick.

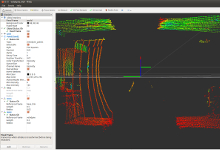

A spinning LiDAR is used to capture a partial or complete spherical view of a robot’s environment using a laser sensor. They are typically used for localization or manipulation tasks on outdoor mobile robots, where it’s important to capture the entire scene as one 3D point cloud.Robotics researchers often construct their own spinning LiDAR because doing so is cheaper than buying an off-the-shelf 3D LiDAR such as the Velodyne HDL-64 or Ocular Robotics’ RobotEye RE05. A common approach is to use a planar 2D LiDAR from SICK, or Hokuyo, and attach it to a motorized base. The LiDAR beam is pitched up-and-down (“knodding” [1]) or rotated on a horizontal axis (either “spinning” [2] or “lapping” [3]).

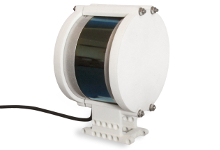

Recently multi-beam LiDAR sensors have appeared on the market, such as the Ibeo LUX (with 4 beams) and Velodyne VLP-16 (with 16 beams). These are designed for automotive applications and are priced in between the 2D planar LiDAR sensors and the top-of-the-line 3D LiDAR sensors. The goal of this experiment was to build a novel spinning LiDAR, by rotating a multi-beam 3D sensor on a vertical axis. To the best of our knowledge this is the first spinning LiDAR using a Velodyne VLP-16.

Mechanism:

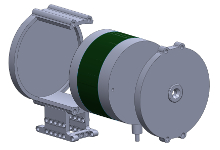

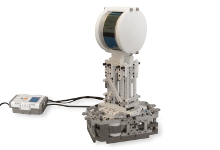

A prototype was quickly assembled using a combination of Lego Technic and 3D printed parts. The rotating joint comprises of a large turntable mechanism driven by a pair of Lego NXT motors. The LiDAR sensor is mounted on top using an adapter bracket.The joint’s rotational position is determined by reading the encoder value from the motor. The gear-train suffers from some noticeable backlash, however the rotational accuracy was sufficient to produce a coherent LiDAR scan for this proof-of-concept.

The standard Lego turntable suffers from two problems: sliding friction and deflection along the rotating axis. One solution is to build a rotating joint using a pair of Lego turntables. Instead we used a large, custom 3D printed turntable [4] that solves both these weaknesses by utilizing roller bearings on a support surface (Fig. 8).

Update:

Since the time of writing, the price of the Velodyne VLP-16 has reduced significantly and this has inspired other roboticists to develop spinning LiDARs using this particular sensor:

Morales et al. performed a detailed analysis of 3D scanning patterns for a spinning VLP-16 [5].

The robot Momaro, which previously used a spinning Hokuyo LiDAR, was upgraded with a spinning VLP-16 [6].

| References: | ||

|

[1] An example of a “knodding” LiDAR sensor can be seen on the the head of DRC Hubo.

See photos here: www.spectrum.ieee.org/automaton/how-kaist-drc-hubo-won-darpa-robotics-challenge |

||

|

[2] A “spinning” LiDAR sensor is used on Carnegie Robotics’ MultiSense device:

www.carnegierobotics.com/products/MultiSense_SL_brochure.pdf |

||

|

[3] The CHIMP robot uses a pair of Hokuyo LiDAR sensors that are rotated sideways such that the overlapping laser beams are “lapping” against surfaces in the environment. See page 217 here:

www.ri.cmu.edu/pub_files/2015/rob21569.pdf |

||

|

[4] Turntable Support, developed by Efferman’s Parts:

www.shapeways.com/product/turntable-support-13-studs-diameter |

||

|

[5] J. Morales, V. Plaza-Leiva, A. Mandow, J. A. Gomez-Ruiz, J. Seron and A. García-Cerezo, “Analysis of 3D Scan Measurement Distribution with Application to a Multi-Beam Lidar on a Rotating Platform”, MDPI Sensors, February 2018.

|

||

|

[6] T. Klamt and S. Behnke, “Anytime Hybrid Driving-Stepping Locomotion Planning”, proceedings of International Conference on Intelligent Robots and Systems (IROS), September 2017.

|

||