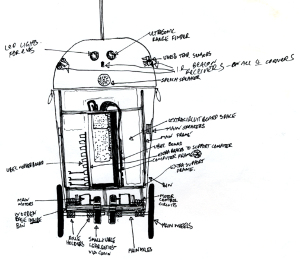

(top) front cut-away view.

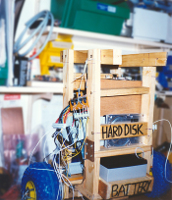

(bottom) detail of front sensors.

This robot was designed to look like the cylinder-shaped robots (droids) you see in films (Fig. 1). The cylinder provides both structural integrity and a pleasing external appearance, so you don’t have to fabricate external panels. However, I could only find plastic bins so I still had to make a frame using wood (lumber) and then the bin slides over the top. Other options would be to use a metal shop vac or clothes dryer drum. The “head” was made from a round plastic washing tub.

The wheels were salvaged from a children’s toy. Two caster wheels stop the robot tipping over. Originally I used motors salvaged from automotive windscreen wipers, but these were bulky and had non-flat mounting holes. Instead, each wheel is driven by a small DC motor with a planetary gearbox and a toothed belt drive to the axle (Fig. 2). The axle is supported by two ball-type bearings on each side, sandwiched in a flange.

|

|

|

The robot has an on-board PC-104 industrial computer, mini ATX power supply and two large 12 volt batteries (Fig. 3-4). I built all the circuits from scratch, including the multi-voltage power supply, an I/O (input-output) expansion board and H-Bridge motor controllers (Fig. 5). A custom I/O expansion card was made to fit in the first PC card slot (Fig. 4).

This project was mainly an experiment in mechanical design for robots, with various iterations of component layout and drive-train. The robot could be driven remotely or follow a programmed path, however it had no sensors and so autonomy was limited.